- Home

- M-Box

- What is M-Box?

- Video Library

- What is M-Box Monitoring System

- Monitor Injection Moulding and Die Casting Machines

- Monitor Mould Making and Metal Fabrication

- Monitor Assembly Lines and Operations

- Monitor Welding

- M-Box Components & Infrastructure

- Increase Factory Efficiency

- Monitor Electricity Consumption

- Instant Notifications Alert System

- Auto Reporting

- Fully Protected and Secure System

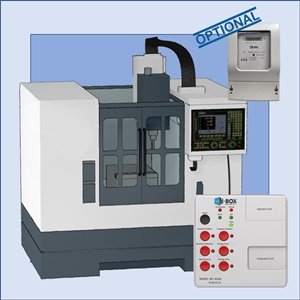

- M-Box Models and Components

- How it Works

- Getting Started with M-Box

- FAQ

- User Support Articles

- Scanning

- For Whom

- Insight

- About Us

- Pricing

English

English